|

Quick-Info-Page SBB Battery Redesign - Technisches |

|

In Kooperation mit SBB |

|

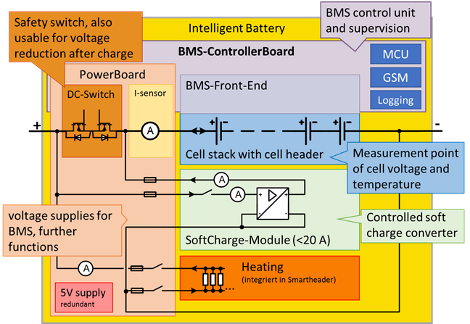

Further Innovation: · Internal 800 W soft charge converter 20 A · Heating 60 W each cell (+10K in 24 min) · Fully operation (charging and discharging) -20°C to 45°C · Space reduction of 50 % · Controlled chargng operation as flexible as the different board net systems · Overal less expensive than current solution: Reduced energy consumption and lower life cycle costs due to Wearout-dependent service life thanks to diagnostic system |

|

Die Bordnetz-Batterie im |

|

Features |

Battery Status quo |

Eval. model BFH |

|

Energy at 3h-discharge |

6.1 kWh @ +20°C 2.9 kWh @ -20°C |

6.5 kWh @ +20°C 3.5 kWh @ -20°C |

|

Nominal Pack Voltage |

36 V (2 x 9 cells) |

35.2 V (11 cells) |

|

Technology / Chemistry |

Lead-acid (VRLA) |

LiFeYPO4 (LFYP) |

|

System weight |

334 kg (in 2 troughs) |

110 kg (-67%) |

|

Energy density at cell level (3h-discharge) |

23 Wh/kg @ +20°C 14 Wh/kg @ -20°C |

105 Wh/kg @ +20°C 71 Wh/kg @ -20°C |

|

Lifetime at given profile |

5-8 Years |

12 – 20 Years |

|

acquisition costs |

CHF 2'500.- |

CHF 4'500.- |

|

Diagnostics, Monitoring, Features |

-Charging is controlled by external charger without taking care of battery's health -Charger meassures temperature in battery-room only |

Internal intelligence: -Monitoring of voltage and temperature even on cell level -current monitoring -Semiconductor-Main switch |